When inspecting the quality of a 22Cr duplex stainless steel forging flange, it was found that some forgings had particularly poor toughness. Analysis of the reasons revealed that the fundamental reason for the decrease in toughness of the 22Cr duplex stainless steel flange was the formation of intermetallic precipitates in its microstructure. When the intermetallic precipitates reach a certain level, the toughness of the material will significantly decrease.

In the ever-evolving world of metallurgy and manufacturing, the demand for stronger, more corrosion-resistant, and cost-effective materials continues to shape industrial practices. One such material that has been gaining considerable attention in forging applications is Stainless Steel SAF2304, a duplex stainless steel alloy known for its excellent combination of mechanical strength and corrosion resistance.

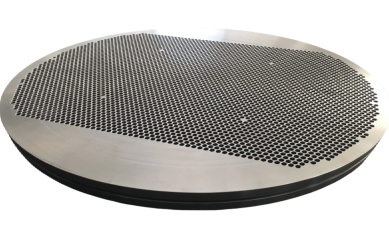

Stainless steel forging has long been recognized as a critical process in producing high-quality industrial components, especially where strength, corrosion resistance, and dimensional precision are paramount. Among the various stainless steel grades, SUS316L stands out due to its superior corrosion resistance and excellent mechanical properties. When forged into tube sheets, SUS316L stainless steel offers unmatched performance in demanding industrial environments such as power plants, chemical processing, and marine applications.