| Availability: | |

|---|---|

| Quantity: | |

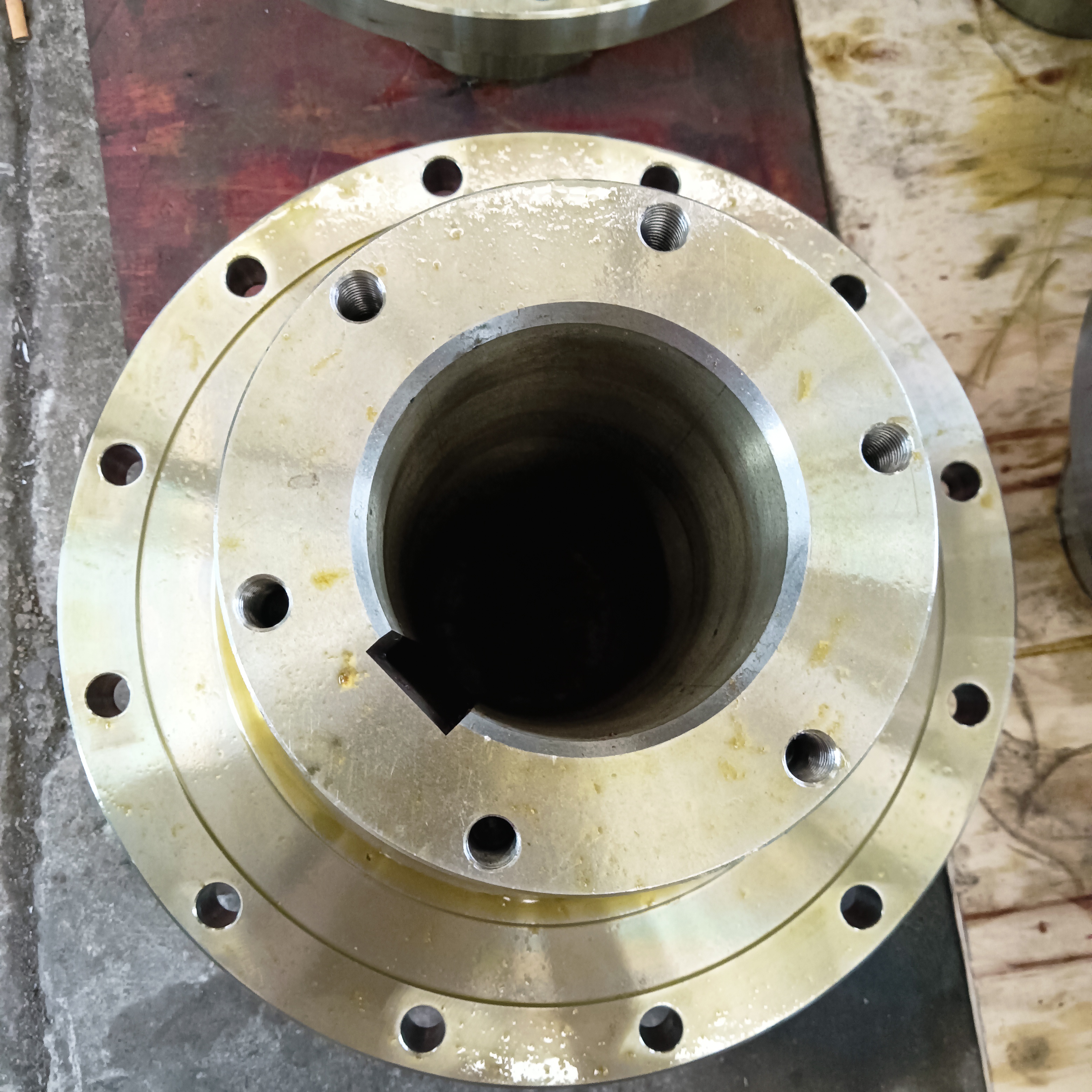

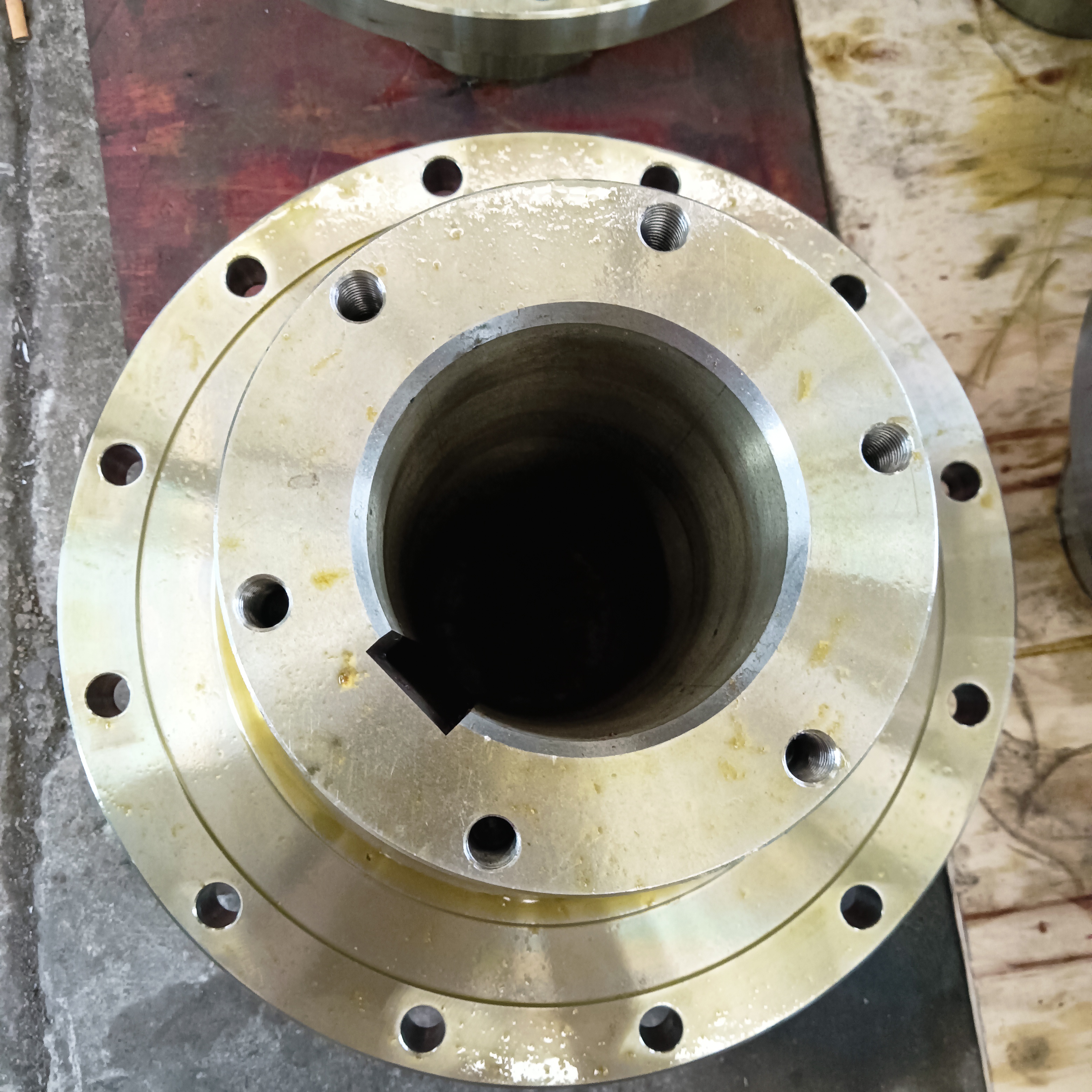

FORGE -DS-OD346*L370

ETERNAL

The Surface Rust Prevention Hollow Shaft is a lightweight, high-strength transmission component designed for automotive transmission systems, wind power generation, and aerospace equipment. Produced by ETERNAL (model: FORGE-DS-OD346*L370), it features a unique hollow cavity structure, stepped outer cylinder, and external/internal key grooves—optimizing torque transmission and weight reduction. Made from C45 carbon structural steel, it leverages C45’s balanced mechanical properties (strength + ductility) and undergoes professional surface rust prevention treatment to resist corrosion in outdoor or humid environments. Unlike solid shafts, its hollow design reduces weight by 20%-30% without compromising load-bearing capacity, making it ideal for weight-sensitive applications.

Parameter | Specification |

Brand | ETERNAL |

Model | FORGE-DS-OD346*L370 |

Material | C45 carbon structural steel |

Dimensions | OD346mm × L370mm (custom OD/length available) |

Chemical Composition | C: 0.42%-0.47%, Si: 0.17%-0.37%, Mn: 0.5%-0.8%, P/S ≤ 0.045% |

Manufacturing Process | Forging → Rough machining → Heat treatment → Final processing → Surface rust prevention |

Surface Treatment | Anti-rust coating (resists salt spray, moisture, and industrial chemicals) |

Core Advantages | Balanced performance, convenient processing, controllable cost |

Application Compatibility | Automotive, wind power, aerospace, machine tool spindles, generators |

C45 steel advantages: As a mainstream carbon steel, C45 offers balanced performance (sufficient strength for transmission loads + ductility to avoid brittle fracture), convenient processing (easy to forge and machine), and controllable cost (suitable for mass production).

Surface rust prevention treatment: The anti-rust coating forms a protective barrier, extending service life by 50% compared to untreated C45 shafts in outdoor environments.

Hollow cavity design: Reduces weight to improve energy efficiency (e.g., in automotive transmissions) and eases internal cable/fluid routing for complex systems.

Precision machining: Stepped outer cylinder and key grooves ensure accurate alignment with mating components, minimizing torque loss during transmission.

Standardized production: Strict forging (enhances material density) and heat treatment (improves machinability) processes guarantee consistent dimensional accuracy and performance.

Wide customization: Supports custom outer diameters (from 50mm to 500mm) and lengths to fit specific equipment models (e.g., large wind turbine shafts).

| GB | ГOCT | EN | DIN | W.N. | JIS | AISI/SAE | |

| 15CrMn | 16MnCr5 | 16MnCr5 | 1.7131 | 5115 | |||

| 20CrMn | 20MnCr5 | 20MnCr5 | 1.7147 | 5120 | |||

| 12CrMo | 12XM | 13CrMo44 | 1.7335 | 4119 | |||

| 15CrMo | 15XM | 15CrMo5 | 1.7262 | SCM415 | |||

| 20CrMo | 20XM | 20CrMo5 | 1.7264 | SCM420 | 4118 | ||

| 25CrMo | 30XM | 25CrMo4 | 1.7218 | ||||

| 30CrMo | SCM430 | 4130 | |||||

| 35CrMo | 35XM | 34CrMo4 | 1.722 | SCM435 | 4135 | ||

| 42CrMo | EN19 | 42CrMo4 | 1.7225 | SCM440 | 4140 | ||

| 50CrMo4 | 1.7228 | ||||||

| 40Cr | 40X | 41Cr4 | |||||

| 38XC | |||||||

| 25Cr2MoV | 25X2M1Φ | 24CrMoV55 | 1.7733 | ||||

| 50CrVA | 50CrV4 | 1.8159 | SUP10 | ||||

| 31CrMoV9 | 1.8519 | ||||||

| GCr15 | 100Cr6 | 100Cr6 | 1.3505 | 52100 | |||

| 20CrNiMo | 20XHM | 20NiCrMo2-2 | 21NiCrMo2 | 1.6523 | SNCM220 | 8620 | |

| 20XH3A | |||||||

| 20X2H4A | |||||||

| 17CrNiMo6 | 1.6587 | ||||||

| 18CrNiMo7-6 | 1.6587 | ||||||

| 34CrNiMo6 | 1.6582 | VCN150 | |||||

| 34NiCrMo16 | 35NiCrMo16 | 1.2766 | |||||

| 30CrNiMo8 | 1.658 | VCN200 | |||||

| 39NiCrMo3 | 1.651 | ||||||

| 34CrAlNi7 | 1.855 | ||||||

| 38CrMoAl | 38X2MОA | 41CrAlMo7 | 1.8509 | ||||

| 40CrNiMo | EN24 | 40NiCrMo8-4 | 1.6562 | SNCM439 | 4340 | ||

| 40CrNi | 40XH | 40NiCr6 | 1.5711 | ||||

| 20CrMnMo | 18XTM | SCM421 | |||||

| 40CrMnMo | 40XTM | SCM440 | |||||

| 30XTCA | |||||||

| 38XTH | |||||||

| 40XH2MA | |||||||

| 40X2H2MA | |||||||

| 38XH3MA | |||||||

| 38XH3MΦA(chǔ) |

The Surface Rust Prevention Hollow Shaft is essential in:

Automotive transmission systems: Transmitting torque between the engine and gearbox, with rust prevention resisting road salt and rainwater corrosion.

Wind power generation: Used in wind turbine drive trains, where the hollow design reduces tower load and anti-rust treatment withstands outdoor weather (snow, humidity).

Aerospace industry: Lightweight structure meets aircraft auxiliary drive weight constraints, ensuring reliable torque transmission at high altitudes.

Machine tool spindles: Provides stable rotation for precision machining tools, with rust prevention maintaining spindle accuracy over long-term use.

Generators: Connecting rotor and stator components in power plants, where corrosion resistance prevents performance degradation from moisture.

C45 steel balances strength, machinability, and cost—critical for transmission components. It avoids the high cost of alloy steels while providing enough strength to handle typical drive loads.

The treatment passes 500-hour salt spray testing, meaning it can resist corrosion in coastal or industrial areas for 5+ years under normal use.

Compared to a solid C45 shaft of the same outer diameter, the hollow design reduces weight by 20%-30%, which improves fuel efficiency in automobiles and reduces structural stress in wind turbines.

The Surface Rust Prevention Hollow Shaft is a lightweight, high-strength transmission component designed for automotive transmission systems, wind power generation, and aerospace equipment. Produced by ETERNAL (model: FORGE-DS-OD346*L370), it features a unique hollow cavity structure, stepped outer cylinder, and external/internal key grooves—optimizing torque transmission and weight reduction. Made from C45 carbon structural steel, it leverages C45’s balanced mechanical properties (strength + ductility) and undergoes professional surface rust prevention treatment to resist corrosion in outdoor or humid environments. Unlike solid shafts, its hollow design reduces weight by 20%-30% without compromising load-bearing capacity, making it ideal for weight-sensitive applications.

Parameter | Specification |

Brand | ETERNAL |

Model | FORGE-DS-OD346*L370 |

Material | C45 carbon structural steel |

Dimensions | OD346mm × L370mm (custom OD/length available) |

Chemical Composition | C: 0.42%-0.47%, Si: 0.17%-0.37%, Mn: 0.5%-0.8%, P/S ≤ 0.045% |

Manufacturing Process | Forging → Rough machining → Heat treatment → Final processing → Surface rust prevention |

Surface Treatment | Anti-rust coating (resists salt spray, moisture, and industrial chemicals) |

Core Advantages | Balanced performance, convenient processing, controllable cost |

Application Compatibility | Automotive, wind power, aerospace, machine tool spindles, generators |

C45 steel advantages: As a mainstream carbon steel, C45 offers balanced performance (sufficient strength for transmission loads + ductility to avoid brittle fracture), convenient processing (easy to forge and machine), and controllable cost (suitable for mass production).

Surface rust prevention treatment: The anti-rust coating forms a protective barrier, extending service life by 50% compared to untreated C45 shafts in outdoor environments.

Hollow cavity design: Reduces weight to improve energy efficiency (e.g., in automotive transmissions) and eases internal cable/fluid routing for complex systems.

Precision machining: Stepped outer cylinder and key grooves ensure accurate alignment with mating components, minimizing torque loss during transmission.

Standardized production: Strict forging (enhances material density) and heat treatment (improves machinability) processes guarantee consistent dimensional accuracy and performance.

Wide customization: Supports custom outer diameters (from 50mm to 500mm) and lengths to fit specific equipment models (e.g., large wind turbine shafts).

| GB | ГOCT | EN | DIN | W.N. | JIS | AISI/SAE | |

| 15CrMn | 16MnCr5 | 16MnCr5 | 1.7131 | 5115 | |||

| 20CrMn | 20MnCr5 | 20MnCr5 | 1.7147 | 5120 | |||

| 12CrMo | 12XM | 13CrMo44 | 1.7335 | 4119 | |||

| 15CrMo | 15XM | 15CrMo5 | 1.7262 | SCM415 | |||

| 20CrMo | 20XM | 20CrMo5 | 1.7264 | SCM420 | 4118 | ||

| 25CrMo | 30XM | 25CrMo4 | 1.7218 | ||||

| 30CrMo | SCM430 | 4130 | |||||

| 35CrMo | 35XM | 34CrMo4 | 1.722 | SCM435 | 4135 | ||

| 42CrMo | EN19 | 42CrMo4 | 1.7225 | SCM440 | 4140 | ||

| 50CrMo4 | 1.7228 | ||||||

| 40Cr | 40X | 41Cr4 | |||||

| 38XC | |||||||

| 25Cr2MoV | 25X2M1Φ | 24CrMoV55 | 1.7733 | ||||

| 50CrVA | 50CrV4 | 1.8159 | SUP10 | ||||

| 31CrMoV9 | 1.8519 | ||||||

| GCr15 | 100Cr6 | 100Cr6 | 1.3505 | 52100 | |||

| 20CrNiMo | 20XHM | 20NiCrMo2-2 | 21NiCrMo2 | 1.6523 | SNCM220 | 8620 | |

| 20XH3A | |||||||

| 20X2H4A | |||||||

| 17CrNiMo6 | 1.6587 | ||||||

| 18CrNiMo7-6 | 1.6587 | ||||||

| 34CrNiMo6 | 1.6582 | VCN150 | |||||

| 34NiCrMo16 | 35NiCrMo16 | 1.2766 | |||||

| 30CrNiMo8 | 1.658 | VCN200 | |||||

| 39NiCrMo3 | 1.651 | ||||||

| 34CrAlNi7 | 1.855 | ||||||

| 38CrMoAl | 38X2MОA | 41CrAlMo7 | 1.8509 | ||||

| 40CrNiMo | EN24 | 40NiCrMo8-4 | 1.6562 | SNCM439 | 4340 | ||

| 40CrNi | 40XH | 40NiCr6 | 1.5711 | ||||

| 20CrMnMo | 18XTM | SCM421 | |||||

| 40CrMnMo | 40XTM | SCM440 | |||||

| 30XTCA | |||||||

| 38XTH | |||||||

| 40XH2MA | |||||||

| 40X2H2MA | |||||||

| 38XH3MA | |||||||

| 38XH3MΦA(chǔ) |

The Surface Rust Prevention Hollow Shaft is essential in:

Automotive transmission systems: Transmitting torque between the engine and gearbox, with rust prevention resisting road salt and rainwater corrosion.

Wind power generation: Used in wind turbine drive trains, where the hollow design reduces tower load and anti-rust treatment withstands outdoor weather (snow, humidity).

Aerospace industry: Lightweight structure meets aircraft auxiliary drive weight constraints, ensuring reliable torque transmission at high altitudes.

Machine tool spindles: Provides stable rotation for precision machining tools, with rust prevention maintaining spindle accuracy over long-term use.

Generators: Connecting rotor and stator components in power plants, where corrosion resistance prevents performance degradation from moisture.

C45 steel balances strength, machinability, and cost—critical for transmission components. It avoids the high cost of alloy steels while providing enough strength to handle typical drive loads.

The treatment passes 500-hour salt spray testing, meaning it can resist corrosion in coastal or industrial areas for 5+ years under normal use.

Compared to a solid C45 shaft of the same outer diameter, the hollow design reduces weight by 20%-30%, which improves fuel efficiency in automobiles and reduces structural stress in wind turbines.