<button id="ms4aw"></button> <dl id="ms4aw"></dl>

Views: 0 Author: Site Editor Publish Time: 2025-11-08 Origin: Site

The main alloying elements of 22Cr (also known as 2205) duplex stainless steel are about 22% Cr, 5% Ni, 3% Mo, and 0.15% N (mass fraction). Its microstructure contains about 50% (volume fraction) of ferrite and about 50% of austenite. This steel has good mechanical and corrosion resistance properties and is widely used in the petroleum and natural gas industry, marine engineering, and chemical industry. Its excellent performance is guaranteed by its structure. If there are intermetallic precipitates in the microstructure, it will have a certain impact on the material properties.

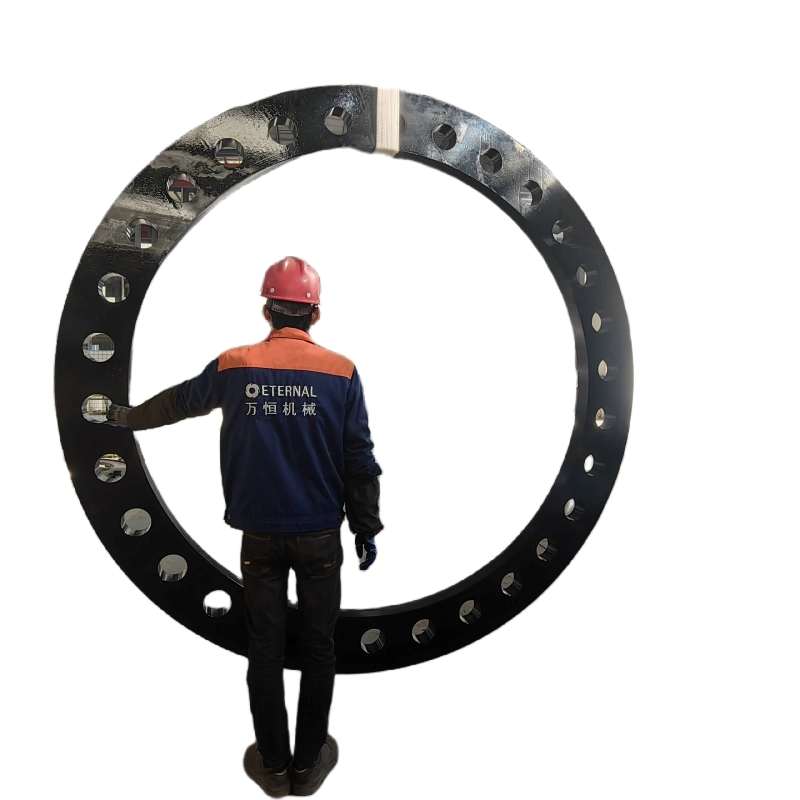

When inspecting the quality of a 22Cr duplex stainless steel forging flange, it was found that some forgings had particularly poor toughness. Analysis of the reasons revealed that the fundamental reason for the decrease in toughness of the 22Cr duplex stainless steel flange was the formation of intermetallic precipitates in its microstructure. When the intermetallic precipitates reach a certain level, the toughness of the material will significantly decrease. The reason for the formation of metal precipitates in the microstructure of 22Cr duplex stainless steel flanges is improper control of forging and heat treatment processes. Low forging temperature, insufficient insulation time for solid solution treatment, and low cooling rate may all cause significant intermetallic precipitates in the material. The forging and solution treatment process parameters (such as temperature and cooling rate) of 22Cr flange material play a crucial role in ensuring the final performance of the flange. Its manufacturing process belongs to a special process, and it is recommended to first conduct process evaluation to determine the process parameters before manufacturing, and then strictly control the operation process; If necessary, conduct random inspections on the organization and performance of workpieces to ensure the performance of key components of important equipment.

<del id="cyaq4"></del> <button id="cyaq4"></button> <dl id="cyaq4"></dl>

<del id="cyaq4"></del>