| Availability: | |

|---|---|

| Quantity: | |

FORGE-R-OD400*L1000

ETERNAL

Product Description

1. Size: OD400*L1000, etc

2. Material: 70Cr3Mo alloy steel

3. Heat treatment: Quenching and tempering

4. Surface treatment: Surface quenching, etc

5. Surface hardness: HRC55-65

6. Quenching layer depth: 25-40mm

7. Transport packaging: Wooden case

8. Service: Customization

9. Warranty period: One year

Application

Steel plate,aluminum plate or foil , copper plate or foil rolling mill in steel plant

Feature

1.Choose high strength forging material

2.Forging raw material choose ESR ingot

3.Long time annealing after forgings to remove inside stress

4.Oil quenching heat treatment to reduce crack risks

5.Double -frequency quenching to reach a high hardness value and depth layer

6.Hardness range : HRC55-65

70Cr3Mo Mechanical Property

Combining high strength and high hardness: Through the process of "quenching and tempering+surface quenching", the effect of "high hardness and wear resistance on the surface, and strong and crack resistance on the core" can be achieved, perfectly adapting to the working conditions where the supporting rollers of the rolling mill need to withstand heavy loads and wear at the same time.

Good hardenability: As an alloy structural steel, its hardenability is better than that of ordinary carbon steel, which can ensure that the center of large-diameter workpieces (such as support rollers) can also obtain uniform microstructure and properties.

Excellent fatigue resistance: Under cyclic loading, the internal stress distribution of the material is uniform, making it less prone to fatigue cracks and extending the service life of the parts.

1.Strength performance:

Tensile strength (Rm) ≥ 1000 MPa

Yield strength (Rel) ≥ 850 MPa

2.Hardness performance: Brinell hardness (HBW) 220-300 HBW (quenched and tempered state) core hardness, ensuring overall toughness; After surface quenching, it can reach 50-60 HRC

3.Resilience performance: Impact absorption energy (Akv) ≥ 25 J (-20 ℃)

4.Plastic properties:

Post fracture elongation (A) ≥ 8%

Sectional shrinkage rate (Z) ≥ 15%

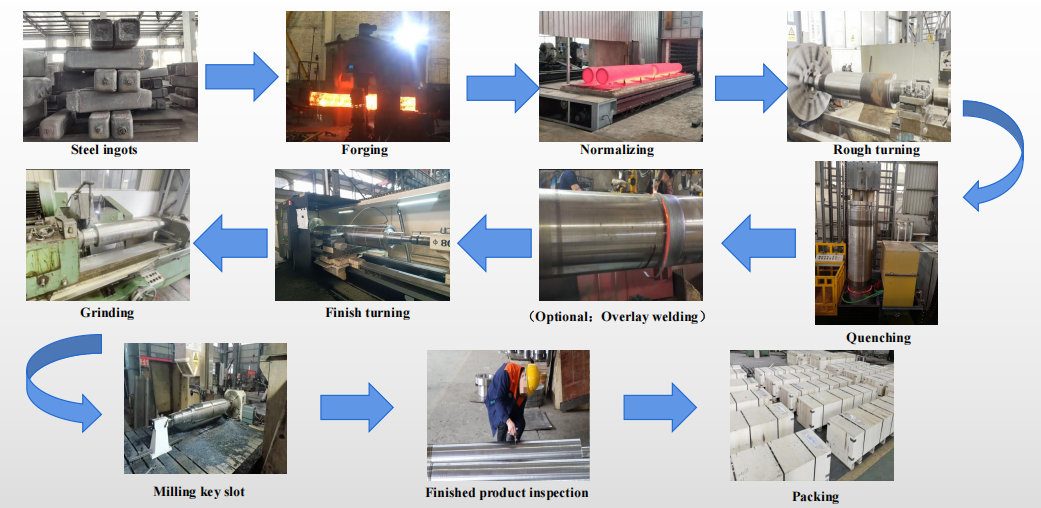

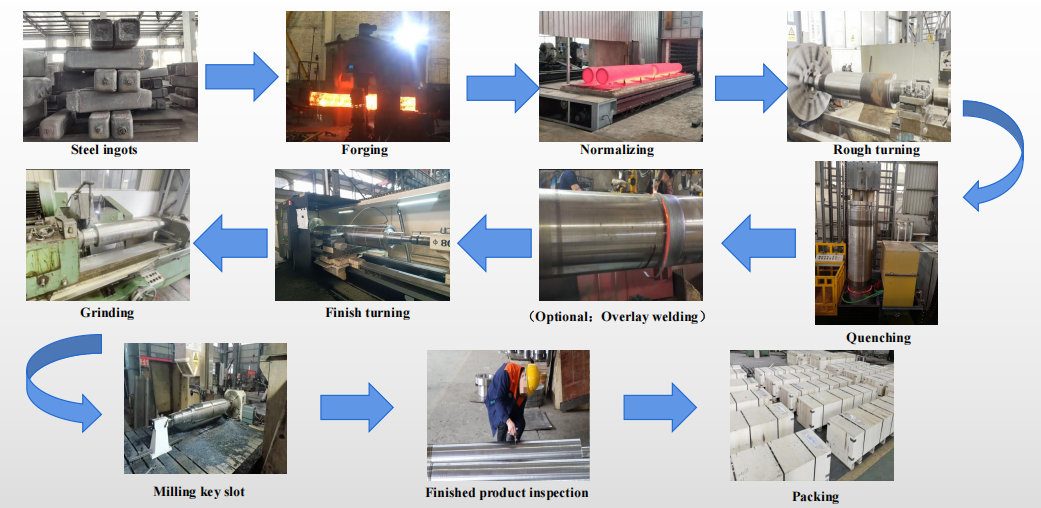

Production Procedure

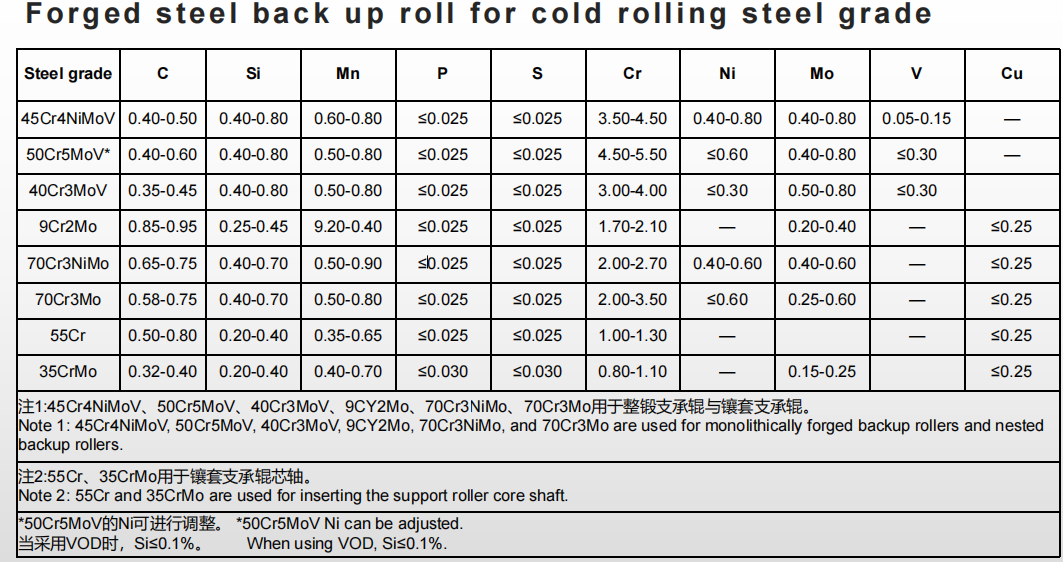

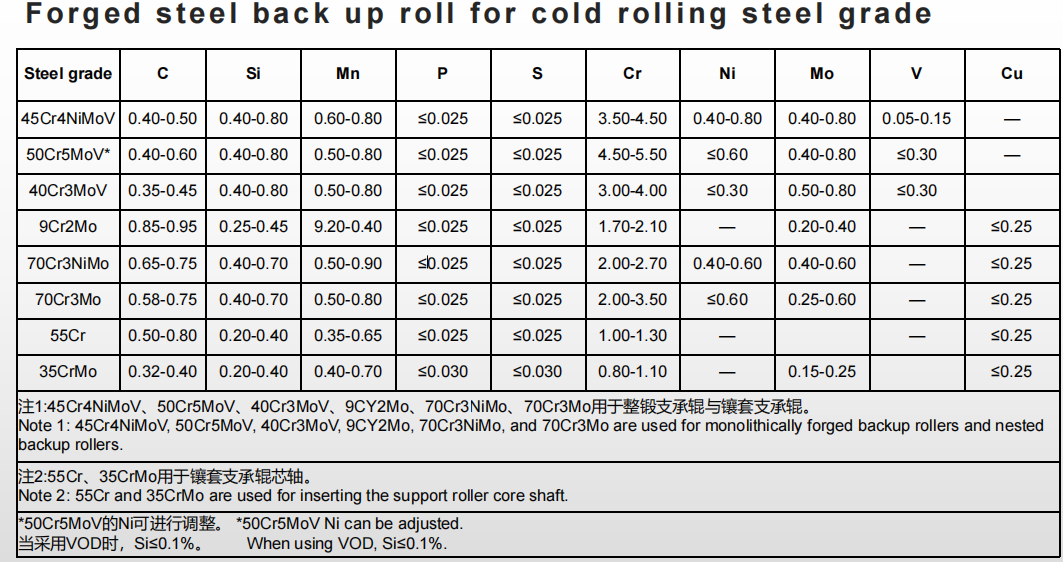

Steel Grade

Product Description

1. Size: OD400*L1000, etc

2. Material: 70Cr3Mo alloy steel

3. Heat treatment: Quenching and tempering

4. Surface treatment: Surface quenching, etc

5. Surface hardness: HRC55-65

6. Quenching layer depth: 25-40mm

7. Transport packaging: Wooden case

8. Service: Customization

9. Warranty period: One year

Application

Steel plate,aluminum plate or foil , copper plate or foil rolling mill in steel plant

Feature

1.Choose high strength forging material

2.Forging raw material choose ESR ingot

3.Long time annealing after forgings to remove inside stress

4.Oil quenching heat treatment to reduce crack risks

5.Double -frequency quenching to reach a high hardness value and depth layer

6.Hardness range : HRC55-65

70Cr3Mo Mechanical Property

Combining high strength and high hardness: Through the process of "quenching and tempering+surface quenching", the effect of "high hardness and wear resistance on the surface, and strong and crack resistance on the core" can be achieved, perfectly adapting to the working conditions where the supporting rollers of the rolling mill need to withstand heavy loads and wear at the same time.

Good hardenability: As an alloy structural steel, its hardenability is better than that of ordinary carbon steel, which can ensure that the center of large-diameter workpieces (such as support rollers) can also obtain uniform microstructure and properties.

Excellent fatigue resistance: Under cyclic loading, the internal stress distribution of the material is uniform, making it less prone to fatigue cracks and extending the service life of the parts.

1.Strength performance:

Tensile strength (Rm) ≥ 1000 MPa

Yield strength (Rel) ≥ 850 MPa

2.Hardness performance: Brinell hardness (HBW) 220-300 HBW (quenched and tempered state) core hardness, ensuring overall toughness; After surface quenching, it can reach 50-60 HRC

3.Resilience performance: Impact absorption energy (Akv) ≥ 25 J (-20 ℃)

4.Plastic properties:

Post fracture elongation (A) ≥ 8%

Sectional shrinkage rate (Z) ≥ 15%

Production Procedure

Steel Grade

content is empty!