| Availability: | |

|---|---|

| Quantity: | |

FORGE-S-OD500*L3000

ETERNAL

Product Description

The supporting wheel axle of the rotary kiln is a key component in the supporting device of the rotary kiln. Its main function is to support the supporting wheel, thereby supporting the weight of the entire rotary kiln cylinder, while transmitting rotational force to enable the cylinder to rotate smoothly on the supporting wheel. In addition, by adjusting the tilt angle of the supporting wheel shaft, the axial movement of the kiln body can be controlled to ensure that the centerline of the kiln body is in a straight line, achieving force balance among the supporting wheels, belts, and bearings of each gear.

They can be installed in factories such as cement plants, lime plants, mines, chemical plants, fertilizer plants, etc

Product Parameters

Heat treatment:Quenching and Tempering

Surface treatment:surface quenching

Hardness:HRC 55-65

Depth of Quenching Layer:2-4mm

Max Diameter:2000mm

Max Length:6000mm

34CrNiMo6 Chemical Composition

| 34CrNiMo6 | C | Si | Mn | Cr | Mo | Ni | P/S |

| 0.30%~0.38% | 0.15% ~ 0.35% | 0.50 %~ 0.80% | 1.3%~1.7% | 0.15%~0.30% | 1.3%~1.7% | ≤0.035% |

Application

Cement Rotary Kiln

Feature

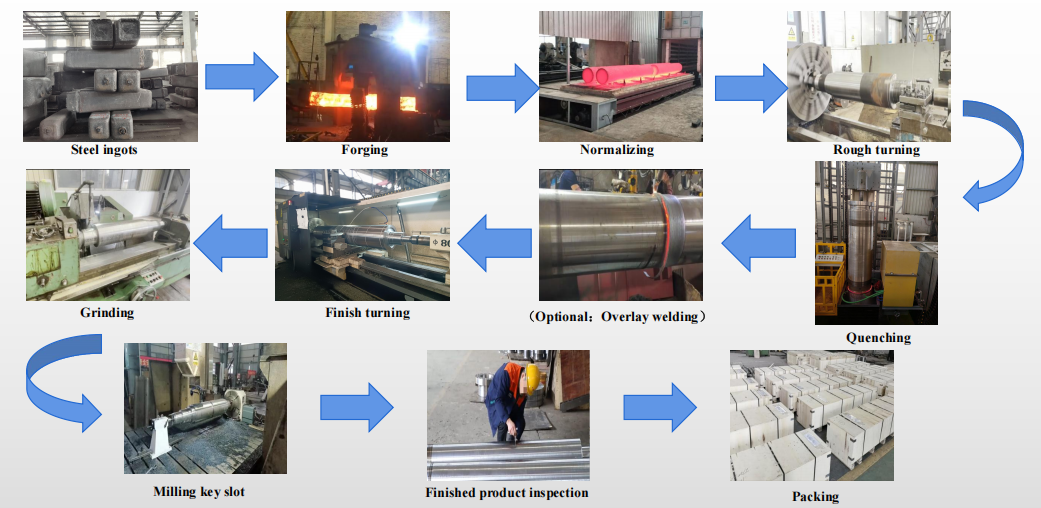

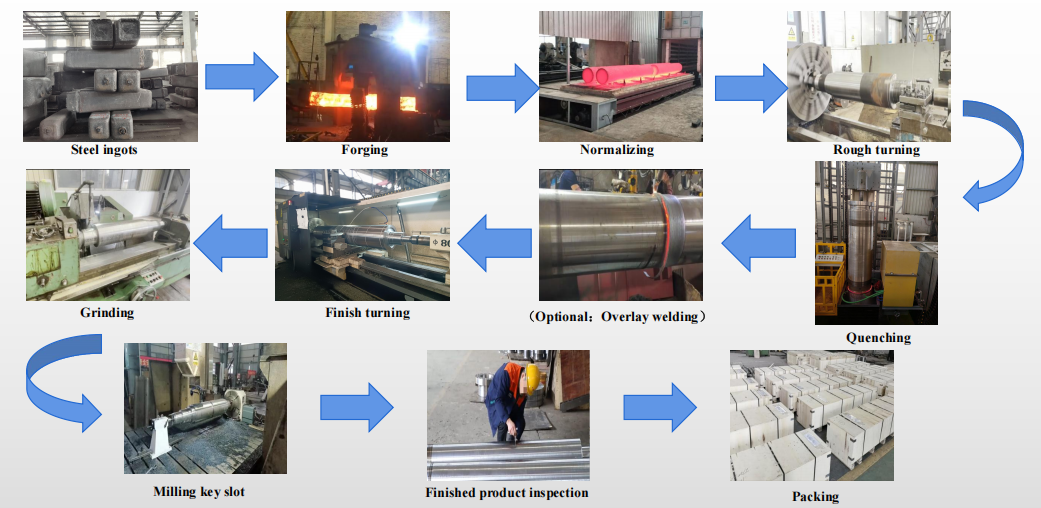

Product Procedure

Forging,rough machining,heat treatment,final processing

Product Description

The supporting wheel axle of the rotary kiln is a key component in the supporting device of the rotary kiln. Its main function is to support the supporting wheel, thereby supporting the weight of the entire rotary kiln cylinder, while transmitting rotational force to enable the cylinder to rotate smoothly on the supporting wheel. In addition, by adjusting the tilt angle of the supporting wheel shaft, the axial movement of the kiln body can be controlled to ensure that the centerline of the kiln body is in a straight line, achieving force balance among the supporting wheels, belts, and bearings of each gear.

They can be installed in factories such as cement plants, lime plants, mines, chemical plants, fertilizer plants, etc

Product Parameters

Heat treatment:Quenching and Tempering

Surface treatment:surface quenching

Hardness:HRC 55-65

Depth of Quenching Layer:2-4mm

Max Diameter:2000mm

Max Length:6000mm

34CrNiMo6 Chemical Composition

| 34CrNiMo6 | C | Si | Mn | Cr | Mo | Ni | P/S |

| 0.30%~0.38% | 0.15% ~ 0.35% | 0.50 %~ 0.80% | 1.3%~1.7% | 0.15%~0.30% | 1.3%~1.7% | ≤0.035% |

Application

Cement Rotary Kiln

Feature

Product Procedure

Forging,rough machining,heat treatment,final processing

content is empty!