| Availability: | |

|---|---|

| Quantity: | |

FORGE-R-OD400*L2500

ETERNAL

Product Description

1. Size: OD400*L2500, etc

2. Material: Alloy steel

3. Heat treatment: quenching and tempering

4. Surface treatment: surface quenching, etc

5. Surface hardness: HRC55-65

6. Quenching layer depth: 2-10mm

7. Transport packaging: wooden case

8. Service: Customization

9. Warranty period: One year

Application

Forged crush rollers are used to crush all kinds of steel,tyre,mineral etc .

Crush roll raw material grade choice

42CrMo , H13 etc .

| 42CrMo | C | Si | Mn | Cr | Mo | P/S |

| 0.38-0.45% | 0.17-0.37% | 0.5-0.8% | 0.9-1.2% | 0.15-0.25% | ≤0.035% |

| H13 | C | Si | Mn | Cr | Mo | V | P/S |

| 0.32-0.45% | 0.8-1.2% | 0.2-0.5% | 4.75-5.5% | 1.1-1.75% | 0.8-1.2% | ≤0.03% |

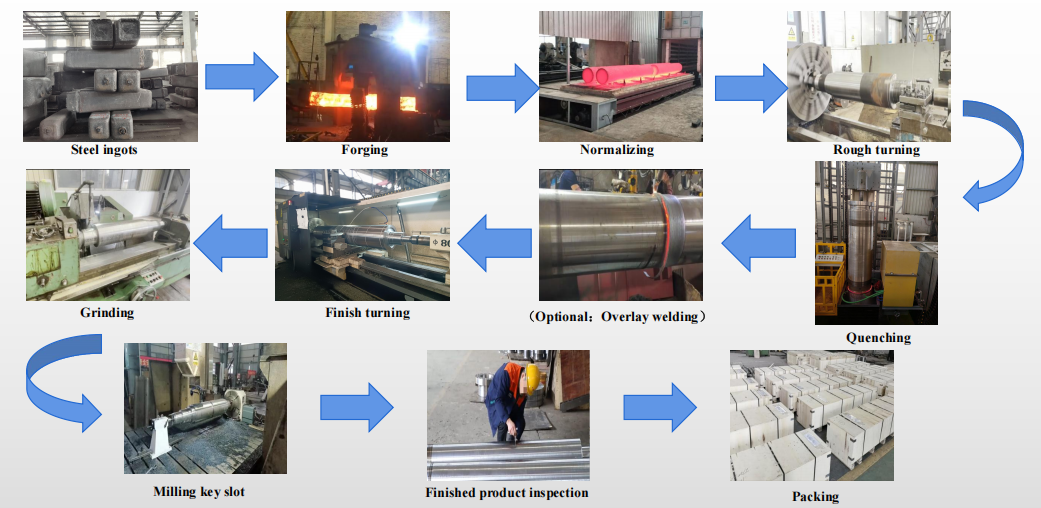

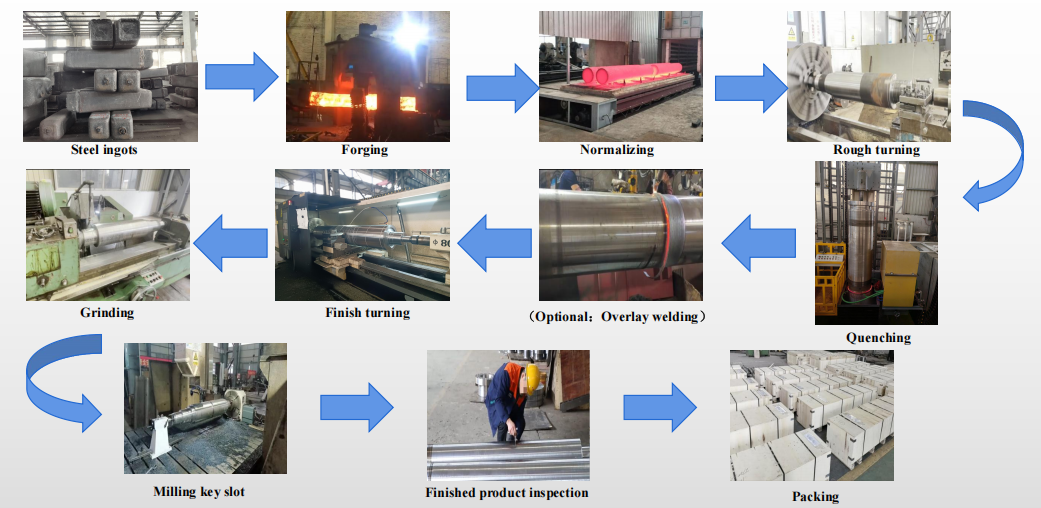

Production Procedure

Forged work roll features

1. Choose high strength forging material

2. Forging raw material choose ESR ingot

3. Long time annealing after forgings to remove inside stress

4. Oil quenching heat treatment to reduce crack risks

5. Double -frequency quenching to reach a high hardness value and depth layer

6. Hardness range: HRC55-65

Product Description

1. Size: OD400*L2500, etc

2. Material: Alloy steel

3. Heat treatment: quenching and tempering

4. Surface treatment: surface quenching, etc

5. Surface hardness: HRC55-65

6. Quenching layer depth: 2-10mm

7. Transport packaging: wooden case

8. Service: Customization

9. Warranty period: One year

Application

Forged crush rollers are used to crush all kinds of steel,tyre,mineral etc .

Crush roll raw material grade choice

42CrMo , H13 etc .

| 42CrMo | C | Si | Mn | Cr | Mo | P/S |

| 0.38-0.45% | 0.17-0.37% | 0.5-0.8% | 0.9-1.2% | 0.15-0.25% | ≤0.035% |

| H13 | C | Si | Mn | Cr | Mo | V | P/S |

| 0.32-0.45% | 0.8-1.2% | 0.2-0.5% | 4.75-5.5% | 1.1-1.75% | 0.8-1.2% | ≤0.03% |

Production Procedure

Forged work roll features

1. Choose high strength forging material

2. Forging raw material choose ESR ingot

3. Long time annealing after forgings to remove inside stress

4. Oil quenching heat treatment to reduce crack risks

5. Double -frequency quenching to reach a high hardness value and depth layer

6. Hardness range: HRC55-65

content is empty!