<del id="sgisu"></del>

| Availability: | |

|---|---|

| Quantity: | |

FORGE-R-350*L1500

ETERNAL

Product Description

Forged work rolls are typically made of forged steel, which provides high toughness and purity, and are widely used in cold rolling, hot rolling, and other types of rolling operations.

Application

The calender is a key equipment for film making, which uses the squeezing and shearing of rollers to make plasticized materials into thin films. The roller is the main component of the calender, which comes into direct contact with the material and applies pressure and heating. It requires sufficient rigidity, strength, hardness, wear resistance, corrosion resistance, and high processing accuracy.

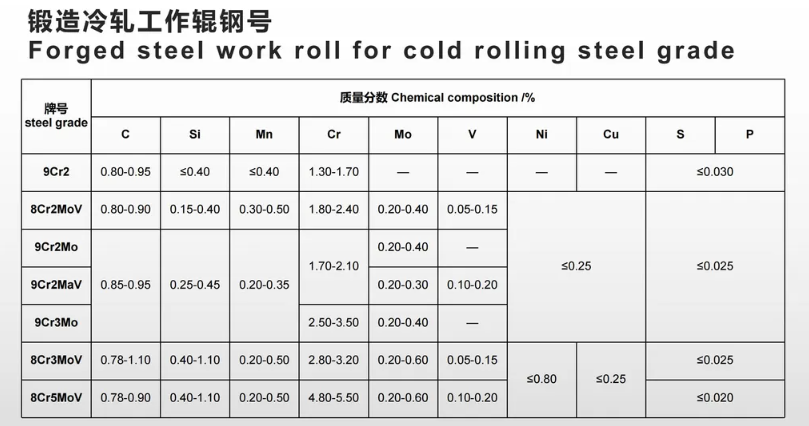

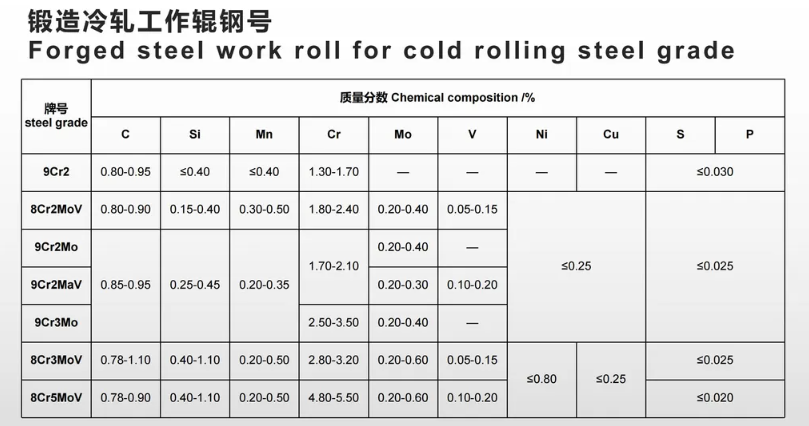

Steel Grade

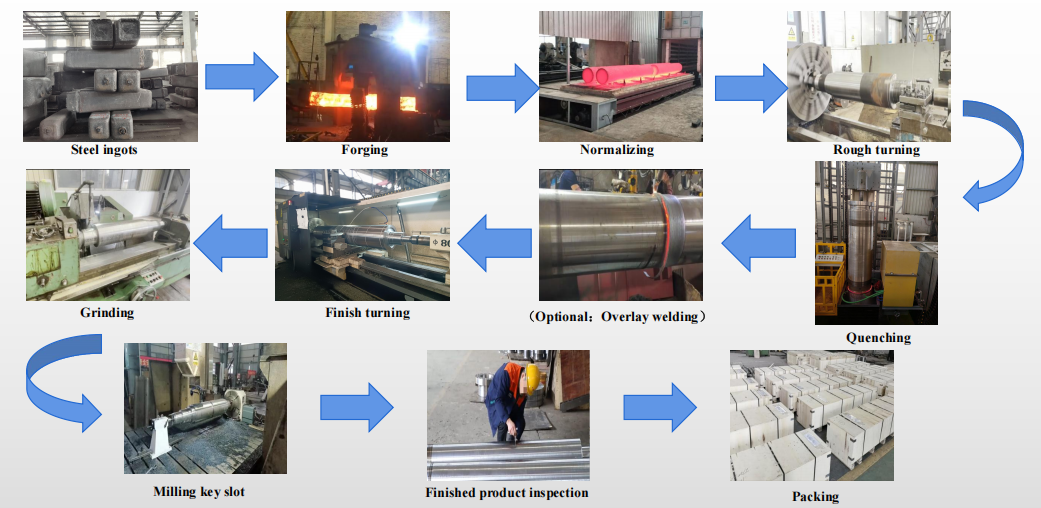

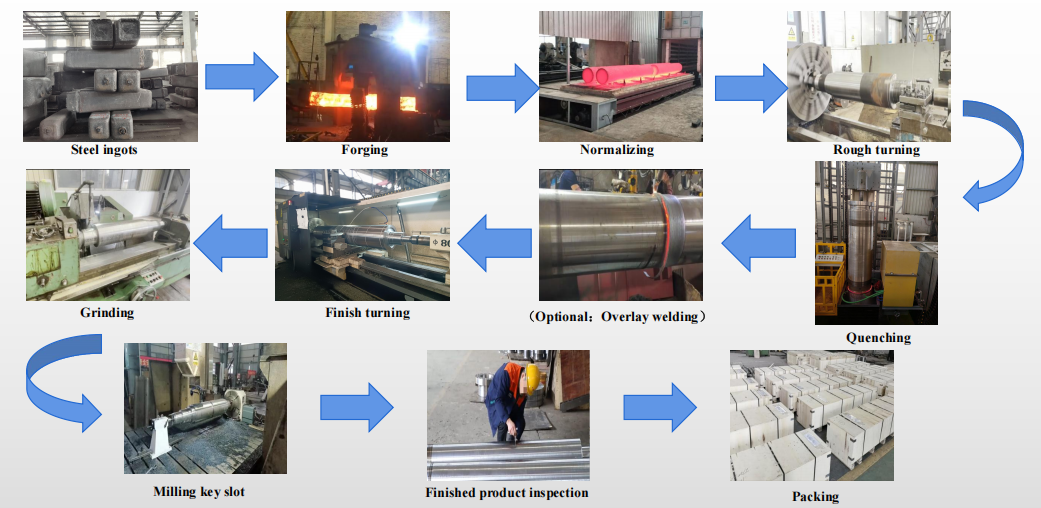

Production Procedure

Forged work roll features

1. Choose high strength forging material

2. Forging raw material choose ESR ingot

3. Long time annealing after forgings to remove inside stress

4. Oil quenching heat treatment to reduce crack risks

5. Double -frequency quenching to reach a high hardness value and depth layer

6. Hardness range: HRC55-65

Product Description

Forged work rolls are typically made of forged steel, which provides high toughness and purity, and are widely used in cold rolling, hot rolling, and other types of rolling operations.

Application

The calender is a key equipment for film making, which uses the squeezing and shearing of rollers to make plasticized materials into thin films. The roller is the main component of the calender, which comes into direct contact with the material and applies pressure and heating. It requires sufficient rigidity, strength, hardness, wear resistance, corrosion resistance, and high processing accuracy.

Steel Grade

Production Procedure

Forged work roll features

1. Choose high strength forging material

2. Forging raw material choose ESR ingot

3. Long time annealing after forgings to remove inside stress

4. Oil quenching heat treatment to reduce crack risks

5. Double -frequency quenching to reach a high hardness value and depth layer

6. Hardness range: HRC55-65

content is empty!