In the ever-evolving world of metallurgy and manufacturing, the demand for stronger, more corrosion-resistant, and cost-effective materials continues to shape industrial practices. One such material that has been gaining considerable attention in forging applications is Stainless Steel SAF2304, a duplex stainless steel alloy known for its excellent combination of mechanical strength and corrosion resistance.

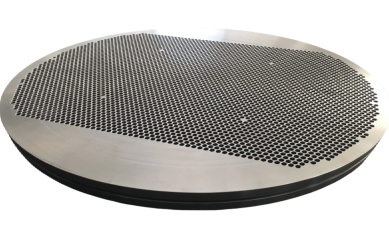

Stainless steel forging has long been recognized as a critical process in producing high-quality industrial components, especially where strength, corrosion resistance, and dimensional precision are paramount. Among the various stainless steel grades, SUS316L stands out due to its superior corrosion resistance and excellent mechanical properties. When forged into tube sheets, SUS316L stainless steel offers unmatched performance in demanding industrial environments such as power plants, chemical processing, and marine applications.

In today’s most challenging industrial environments—from offshore oil rigs and desalination plants to chemical reactors and power generation systems—reliability is non-negotiable. Components must withstand extreme pressures, corrosive media, and fluctuating temperatures without failure. Stainless steel forging, particularly using Stainless Steel SAF2507, has emerged as a key solution for engineers and manufacturers aiming to build durable, high-performance systems.