<strike id="16161"></strike>

Views: 0 Author: Site Editor Publish Time: 2025-10-03 Origin: Site

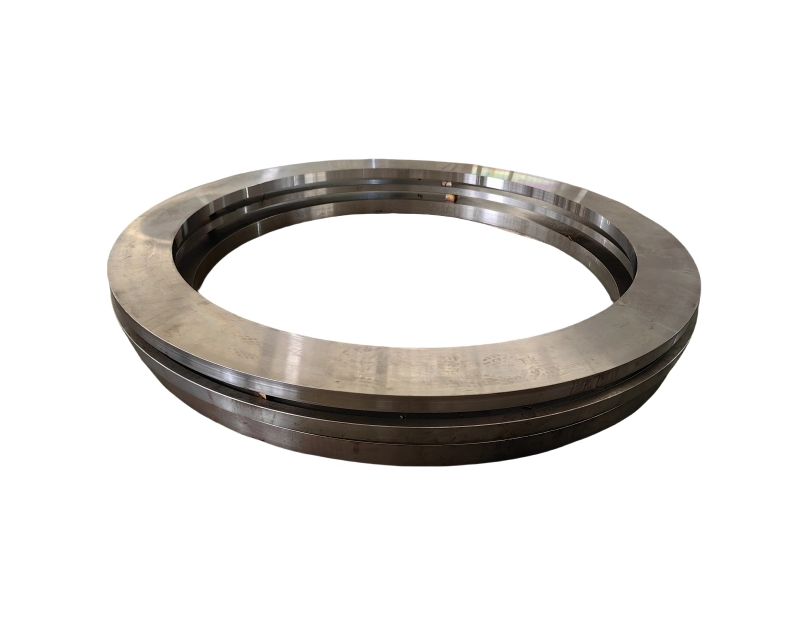

The retaining ring is a key component in large generators, installed at both ends of the rotor to prevent the coil at the rotor end from escaping during high-speed rotation. Due to the alternating effects of enormous centrifugal force, bending stress, thermal loading stress, and high-speed dynamic load, it is required to have sufficiently high strength, a certain yield strength ratio, good toughness, uniform mechanical properties, and minimal residual stress. Due to the influence of corrosive media, it is also required to have stress corrosion resistance to ensure long-term safe operation. The steel used for the retaining ring is mainly Mn18-Cr4 and Mn18-Cr18 austenitic high-strength steel, which are further improved in mechanical properties through deformation strengthening.

1. Technical requirements

The recommended steel is Mn18Cr18N (with a nitrogen mass fraction of 0.6% to 1.2%). Mechanical properties: Rp0.2=1076MPa, Rm=1180MPa, A=17%, Z=30%, aK=60J/cm ^ 2. Physical properties: Magnetic permeability μ ≤ 1.1. The residual stress is below 117MPa, the grain size is at level one, and the forging is required to undergo color inspection and ultrasonic testing after rough machining.

2. Production process and its key points

Self consuming electrodes made of electric furnace steel → electric slag remelting (ESR) → hot forging billet → rough machining → solution treatment → deformation strengthening → stress relief and size stabilization treatment → quality inspection.

3. Hot forging billet

At present, the main process of hot forging blanks is cutting → upsetting → punching → punch pre hole expansion → core shaft elongation → hole expansion forming to the required size. The forging temperature range is 1220-850 ℃. The key technology in forging is homogenization, refinement of microstructure, and prevention of forging cracks

4. Bulging strengthening

The current deformation strengthening methods for retaining rings include hydraulic bulging and wedge block hole expansion strengthening. Hydraulic bulging is an advanced technology that utilizes ultra-high pressure water transmission to strengthen the inner pressure bulging of the protective ring. Due to its uniform deformation and excellent bulging quality, it is recognized as an advanced technology for strengthening the protective ring bulging. The expansion of the wedge block hole is achieved by using the mechanical expansion of the wedge block mold to strengthen the bulging of the protective ring. Its main disadvantage is uneven circumferential deformation.