| Availability: | |

|---|---|

| Quantity: | |

FORGE - R

ETERNAL

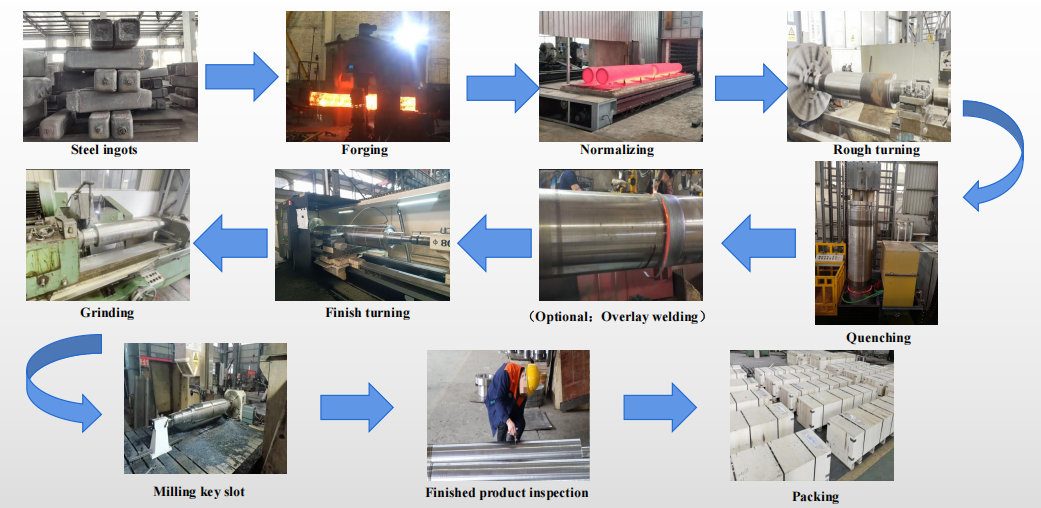

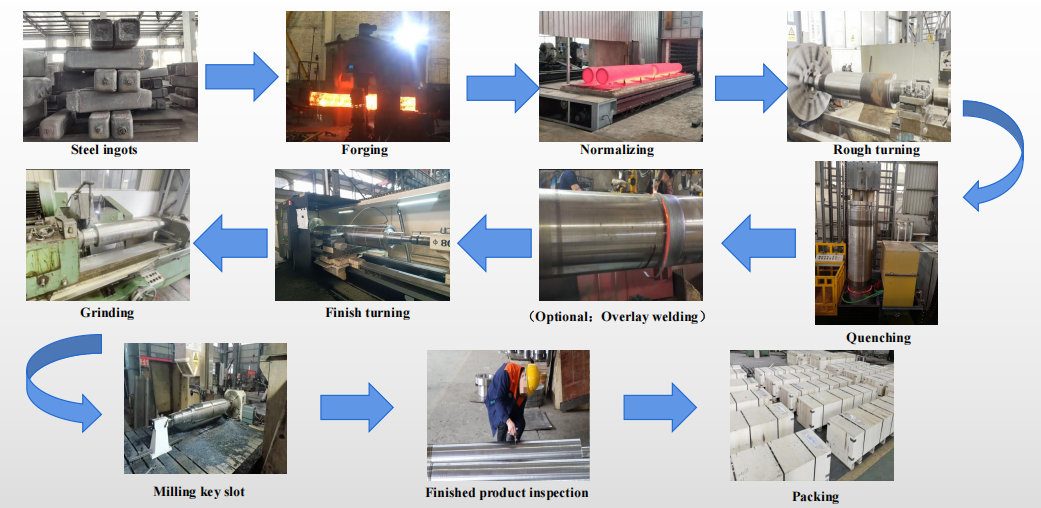

Production Procedure

Application:

1. Steel plate cold rolling mill

2. Aluminum plate cold rolling mill

3. Copper plate cold rolling mill

Feature:

1. Choose high strength forging material

2. Forging raw material choose ESR ingot

3. Long time annealing after forgings to remove inside stress

4. Oil quenching heat treatment to reduce crack risks

5. Double -frequency quenching to reach a high hardness value and depth layer

6. Hardness range: HRC55-65

8Cr3MoV forging steel chemical specification :

| 8Cr3MoV | C | Si | Mn | Cr | Mo | V | P/S |

| 0.78-1.1% | 0.4-1.1% | 0.2-0.5% | 2.8-3.2% | 0.2-0.6% | 0.05-0.15% | ≤0.025% |

8Cr3MoV mechanical property :

The core mechanical properties of 8Cr3MoV are characterized by high hardness, high wear resistance, and moderate toughness, with heat treatment process being the key. The quenching temperature is usually 1050-1100 ℃, and the tempering temperature is 180-220 ℃ (low-temperature tempering to maintain hardness) or 450-550 ℃ (medium temperature tempering to improve toughness).

Hardness: HRC 60-64, the hardness can reach HRC 62-65 after quenching, and maintains high hardness after tempering to meet wear resistance requirements.

Strength and toughness: The tensile strength is about 1800-2200MPa, and the impact toughness α k is 15-25 J/cm ², which combines high strength and certain impact resistance.

Wear resistance and red hardness: containing Cr, Mo, V elements to form carbides, excellent wear resistance; Red hardness is moderate, and it can still maintain good hardness in an environment of 250-300 ℃.

Processing performance: After annealing, the hardness is about HB 229-285, which can be used for cutting such as turning and milling. After quenching, it needs to be ground and precision machined.

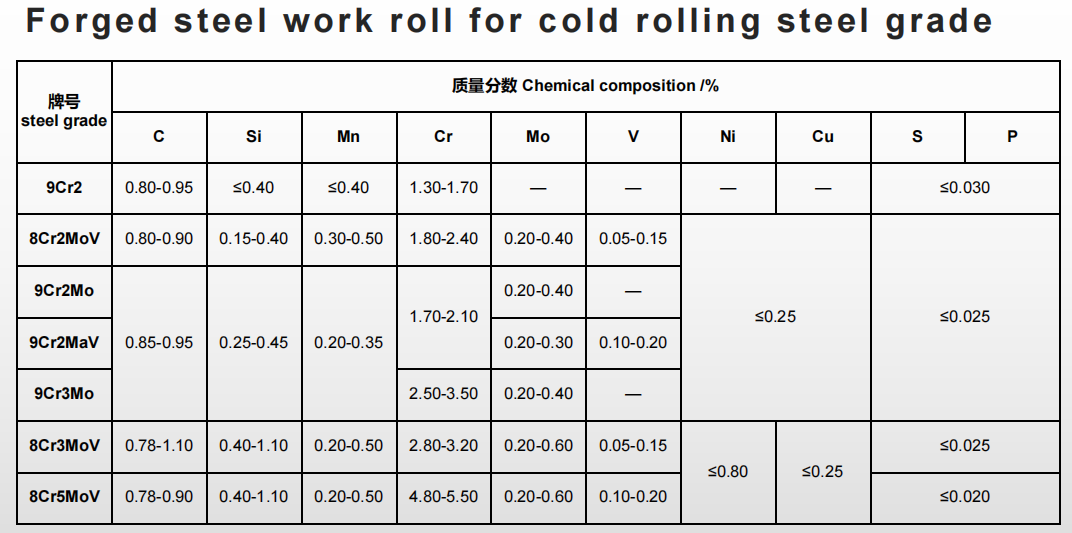

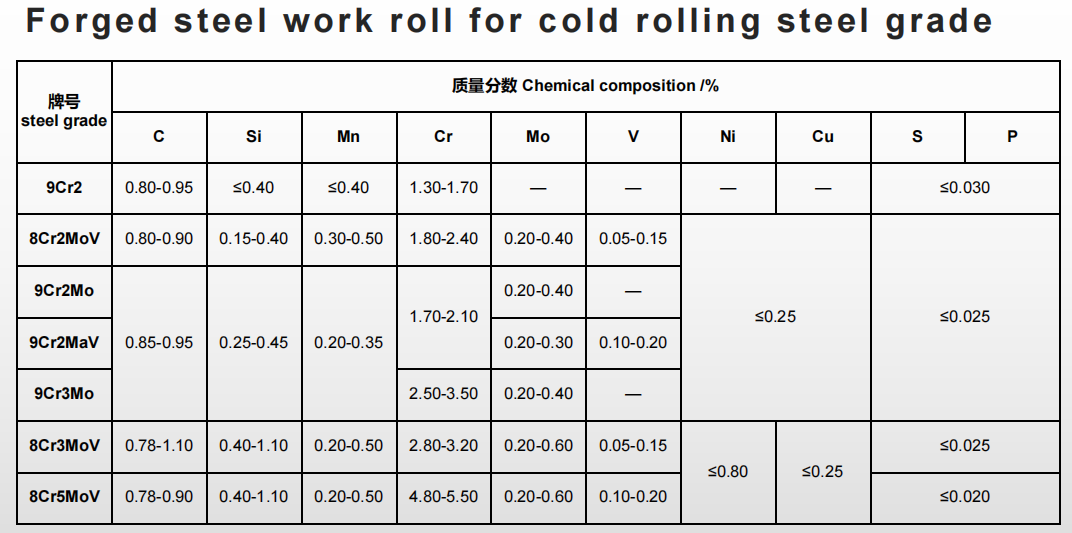

Steel Grade

Production Procedure

Application:

1. Steel plate cold rolling mill

2. Aluminum plate cold rolling mill

3. Copper plate cold rolling mill

Feature:

1. Choose high strength forging material

2. Forging raw material choose ESR ingot

3. Long time annealing after forgings to remove inside stress

4. Oil quenching heat treatment to reduce crack risks

5. Double -frequency quenching to reach a high hardness value and depth layer

6. Hardness range: HRC55-65

8Cr3MoV forging steel chemical specification :

| 8Cr3MoV | C | Si | Mn | Cr | Mo | V | P/S |

| 0.78-1.1% | 0.4-1.1% | 0.2-0.5% | 2.8-3.2% | 0.2-0.6% | 0.05-0.15% | ≤0.025% |

8Cr3MoV mechanical property :

The core mechanical properties of 8Cr3MoV are characterized by high hardness, high wear resistance, and moderate toughness, with heat treatment process being the key. The quenching temperature is usually 1050-1100 ℃, and the tempering temperature is 180-220 ℃ (low-temperature tempering to maintain hardness) or 450-550 ℃ (medium temperature tempering to improve toughness).

Hardness: HRC 60-64, the hardness can reach HRC 62-65 after quenching, and maintains high hardness after tempering to meet wear resistance requirements.

Strength and toughness: The tensile strength is about 1800-2200MPa, and the impact toughness α k is 15-25 J/cm ², which combines high strength and certain impact resistance.

Wear resistance and red hardness: containing Cr, Mo, V elements to form carbides, excellent wear resistance; Red hardness is moderate, and it can still maintain good hardness in an environment of 250-300 ℃.

Processing performance: After annealing, the hardness is about HB 229-285, which can be used for cutting such as turning and milling. After quenching, it needs to be ground and precision machined.

Steel Grade

content is empty!