| Availability: | |

|---|---|

| Quantity: | |

RBM-STABILIZER ,6" to 15",Customized

ETERNAL

Product Specification

1. Size: 6" to 15",Customized

2. Material: Alloy steel

3.Product Procedure:Forging,heat treatment,lathe machining

4. Heat treatment: Quenching and tempering

5. Surface treatment: Tungsten Carbide Hardfacing

6. Surface hardness: HRC40-62

7.Mechanical property:Tensile strength : min 1144MPA, Yield strength : 1034MPA, Impact value :min 68J

8. Transport packaging: Wooden case

9. Service: Customization

10. Warranty period: One year

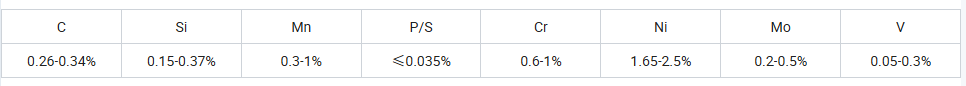

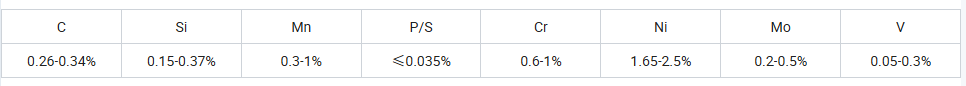

4330V Chemical Composition

AISI 4330V is a high-strength low-alloy steel containing vanadium, which is widely used in harsh fields such as aerospace and petroleum extraction due to its excellent hardenability, impact toughness, and high strength.

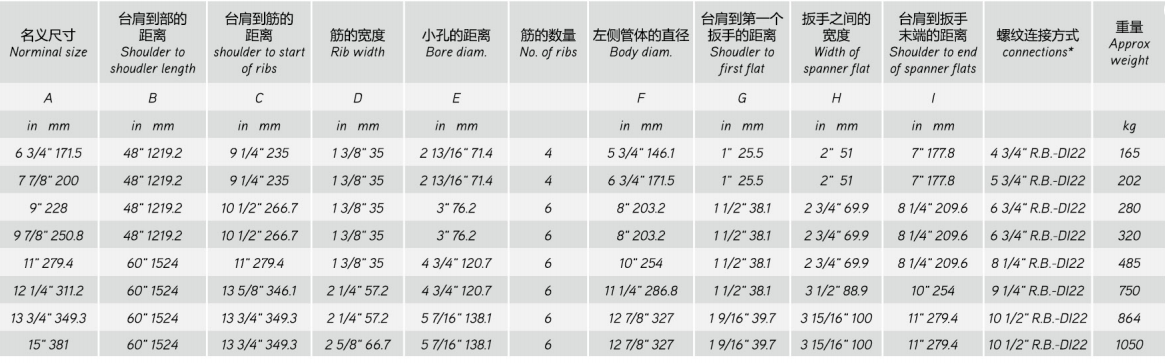

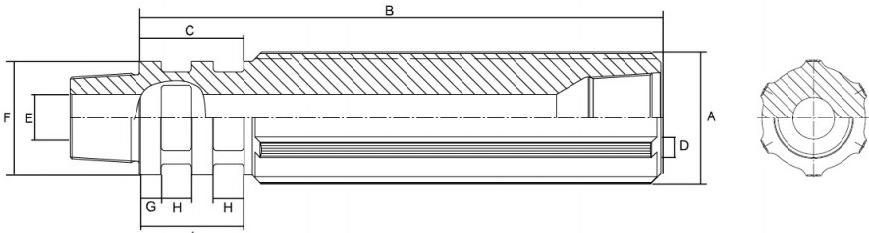

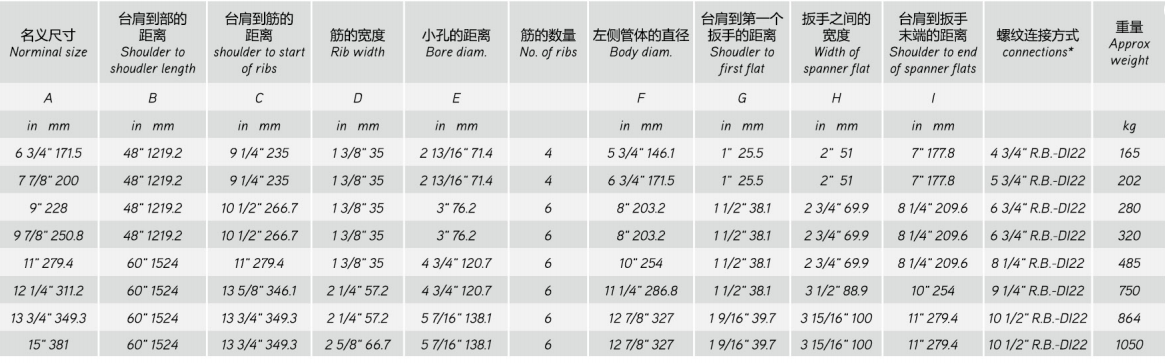

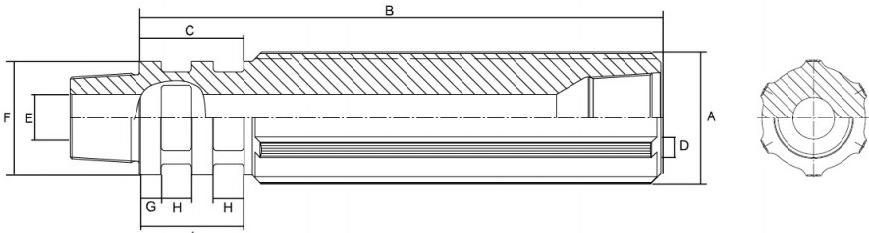

Size and technical specification

Feature

1.Choose high strength forging material, 4140, 4330V, 4330V MOD etc

2.Through quenching and tempering heat treatment, carry out test on each piece forgings

3.Straight rib type: Tungsten carbide insert, weld-on hard facing with wearing material

Application

They are widely applicated on all kinds of underground constructions, including mine shafts, mine passages, hydro power passages, railway traffics, etc.

Product Specification

1. Size: 6" to 15",Customized

2. Material: Alloy steel

3.Product Procedure:Forging,heat treatment,lathe machining

4. Heat treatment: Quenching and tempering

5. Surface treatment: Tungsten Carbide Hardfacing

6. Surface hardness: HRC40-62

7.Mechanical property:Tensile strength : min 1144MPA, Yield strength : 1034MPA, Impact value :min 68J

8. Transport packaging: Wooden case

9. Service: Customization

10. Warranty period: One year

4330V Chemical Composition

AISI 4330V is a high-strength low-alloy steel containing vanadium, which is widely used in harsh fields such as aerospace and petroleum extraction due to its excellent hardenability, impact toughness, and high strength.

Size and technical specification

Feature

1.Choose high strength forging material, 4140, 4330V, 4330V MOD etc

2.Through quenching and tempering heat treatment, carry out test on each piece forgings

3.Straight rib type: Tungsten carbide insert, weld-on hard facing with wearing material

Application

They are widely applicated on all kinds of underground constructions, including mine shafts, mine passages, hydro power passages, railway traffics, etc.

content is empty!