| Availability: | |

|---|---|

| Quantity: | |

Customized

ETERNAL

Product Description

1. Size: Customized

2. Material: Special Stainless Steel

3. Heat treatment: Annealing,/Solution/Aging

4. Surface treatment: Polish/Black Surface

5.Shape:Bar /Plate/Flat

6. Transport packaging: Wooden case

7. Warranty period: One year

Application

The application of special stainless steel for automobiles covers the three core systems of body, power, and chassis, as well as special functional components. It is a key material for automobile safety, durability, and lightweight.

Body and Decoration: Balancing long-lasting appearance and structural safety, used for decorative parts, interior brackets, collision beams, etc.

Exhaust and power: Suitable for high temperature and high load environments, used for various components of the exhaust system, engine gears, etc.

Chassis and Function: Resistant to corrosion and fatigue, used for chassis structural components, suspension components, fluid transmission pipelines, etc.

Special components: for precision manufacturing, wear resistance and other requirements, used for valve seat rings, high-strength bolts, etc.

Feature

The core feature of special stainless steel for automobiles is its adaptability to complex working conditions, with key properties such as corrosion resistance, toughness, and lightweight, and it can meet the special needs of different components.

Outstanding corrosion resistance: It can resist corrosion from the atmosphere, rainwater, road salt, engine oil stains, etc. Especially 316 and duplex steel have strong resistance to chloride ion corrosion, extending the service life of components.

Mechanical performance balance: Balancing strength and toughness, some grades can achieve a combination of high strength and high ductility, suitable for the needs of safe structural components.

High temperature resistance/low temperature stability: High Cr/Ni content grades can withstand temperatures above 1000 ℃, and some ferritic and austenitic steels can still maintain toughness in low temperature environments.

Excellent processing and formability: easy to punch, weld, and cut, able to meet the manufacturing needs of complex vehicle structures, exhaust system irregular parts, etc., and the corrosion resistance is not easily degraded after welding.

Great potential for lightweighting: High strength grades can reduce material thickness, achieve weight reduction compared to traditional steel, and help cars reduce fuel consumption and improve endurance.

Economy and environmental friendliness: The cost of some ferritic stainless steels is lower than that of austenitic steels, and stainless steels can be recycled, which is in line with the environmental trend of the automotive industry.

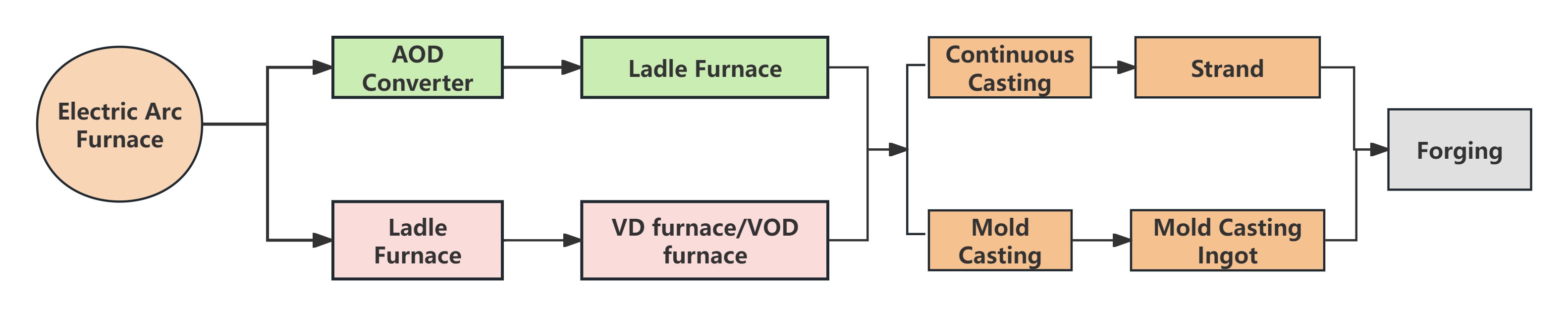

Production Procedure

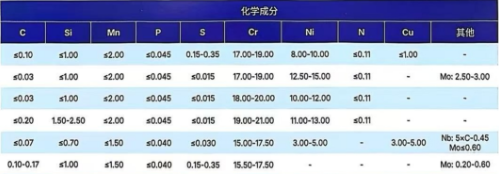

Steel Grade and Chemical Composition

Product Description

1. Size: Customized

2. Material: Special Stainless Steel

3. Heat treatment: Annealing,/Solution/Aging

4. Surface treatment: Polish/Black Surface

5.Shape:Bar /Plate/Flat

6. Transport packaging: Wooden case

7. Warranty period: One year

Application

The application of special stainless steel for automobiles covers the three core systems of body, power, and chassis, as well as special functional components. It is a key material for automobile safety, durability, and lightweight.

Body and Decoration: Balancing long-lasting appearance and structural safety, used for decorative parts, interior brackets, collision beams, etc.

Exhaust and power: Suitable for high temperature and high load environments, used for various components of the exhaust system, engine gears, etc.

Chassis and Function: Resistant to corrosion and fatigue, used for chassis structural components, suspension components, fluid transmission pipelines, etc.

Special components: for precision manufacturing, wear resistance and other requirements, used for valve seat rings, high-strength bolts, etc.

Feature

The core feature of special stainless steel for automobiles is its adaptability to complex working conditions, with key properties such as corrosion resistance, toughness, and lightweight, and it can meet the special needs of different components.

Outstanding corrosion resistance: It can resist corrosion from the atmosphere, rainwater, road salt, engine oil stains, etc. Especially 316 and duplex steel have strong resistance to chloride ion corrosion, extending the service life of components.

Mechanical performance balance: Balancing strength and toughness, some grades can achieve a combination of high strength and high ductility, suitable for the needs of safe structural components.

High temperature resistance/low temperature stability: High Cr/Ni content grades can withstand temperatures above 1000 ℃, and some ferritic and austenitic steels can still maintain toughness in low temperature environments.

Excellent processing and formability: easy to punch, weld, and cut, able to meet the manufacturing needs of complex vehicle structures, exhaust system irregular parts, etc., and the corrosion resistance is not easily degraded after welding.

Great potential for lightweighting: High strength grades can reduce material thickness, achieve weight reduction compared to traditional steel, and help cars reduce fuel consumption and improve endurance.

Economy and environmental friendliness: The cost of some ferritic stainless steels is lower than that of austenitic steels, and stainless steels can be recycled, which is in line with the environmental trend of the automotive industry.

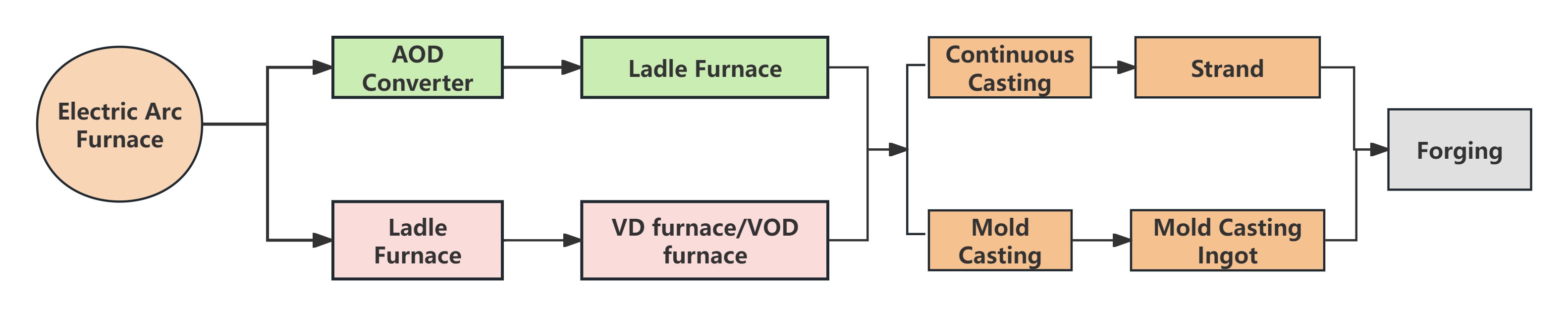

Production Procedure

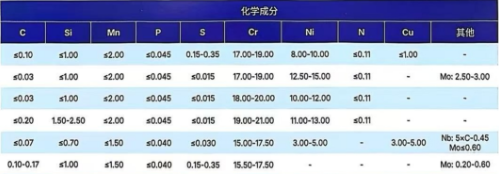

Steel Grade and Chemical Composition

content is empty!