<li id="ickqm"></li>

<li id="ickqm"></li>

| Availability: | |

|---|---|

| Quantity: | |

FORGE-B-OD120*L4500

ETERNAL

Product Description

1. Size: OD120*L4500, etc

2. Material: Alloy 625/718/901,etc.

3. Heat treatment: Annealing,/Solution/Aging

4. Surface treatment: Polish/Black Surface

5.Shape:Round Bar

6. Transport packaging: Wooden case

7. Service: Customization

8. Warranty period: One year

Application

High temperature alloy core is applied in scenarios that require resistance to high temperatures above 600 ℃, corrosion, or complex stresses, with aerospace, energy and power fields as the core, covering multiple industrial and high-end civilian scenarios.

Aerospace field: the most critical application scenario. Core components such as turbine blades, turbine disks, combustion chambers, and guide vanes used in the manufacturing of aviation engines, as well as high-temperature and pressure bearing components such as rocket engine thrust chambers and nozzles, can withstand temperatures above 1000 ℃ and complex stresses.

Energy and power sector: covering sub scenarios such as gas turbines, nuclear power, and thermal power. The turbine blades, combustion chambers, and other components of gas turbines rely on their high temperature resistance characteristics; The fuel cladding and internal components used in nuclear reactors in the field of nuclear power must withstand both high temperatures and radiation corrosion; In the thermal power industry, it is used for boiler superheaters, reheater pipelines, etc. in ultra supercritical units.

Petrochemical industry: suitable for high temperature, high pressure, and highly corrosive environments. For example, equipment such as ethylene cracking furnace tubes, hydrogenation reactors, and reforming reactors can resist medium corrosion and stress damage at high temperatures.

In the field of shipbuilding and ocean engineering, it is used as the core component of ship gas turbines, as well as high-temperature heat exchange equipment and oil and gas transmission pipelines for offshore platforms, which can withstand high temperatures, high humidity, and corrosion in marine environments.

Other important applications

Automotive industry: mainly used for turbochargers and exhaust system components in high-performance racing cars or high-end models, to enhance the engine's high-temperature resistance and power performance.

In the medical field, cobalt based high-temperature alloys are mainly used to manufacture artificial joints, dental implants, etc., with biocompatibility, wear resistance, and high temperature resistance (sterilization process) characteristics.

In the field of metallurgy and machinery, high-temperature furnace components, heat treatment fixtures, and wear-resistant and corrosion-resistant parts that need to work in high-temperature environments for a long time in mechanical manufacturing are used in the metallurgical industry.

Feature

The core characteristics of high-temperature alloys are high temperature resistance, strong stability, corrosion resistance, and the ability to work reliably for a long time under high temperatures above 600 ℃ and complex stresses.

1.Excellent high-temperature strength: above 600 ℃, it still maintains high tensile strength, creep resistance, and fatigue resistance, and will not undergo significant deformation or fracture due to high temperature.

Strong antioxidant and anti-corrosion ability: A dense oxide film forms on the surface under high temperature environment, which can resist oxidation, gas corrosion, acid and alkali medium corrosion, etc., extending the service life.

2.High organizational stability: It is mostly a single-phase austenitic structure. When used at high temperatures for a long time, the organizational structure is not easily changed and the performance deteriorates slowly.

3.Comprehensive mechanical performance balance: It has certain plasticity, toughness, and wear resistance, can adapt to stress changes under complex working conditions, and has high reliability after processing and forming.

4.Suitable for extreme environments: It can withstand multiple harsh conditions such as high temperature, high pressure, radiation, and vibration, and is the core material under extreme working conditions.

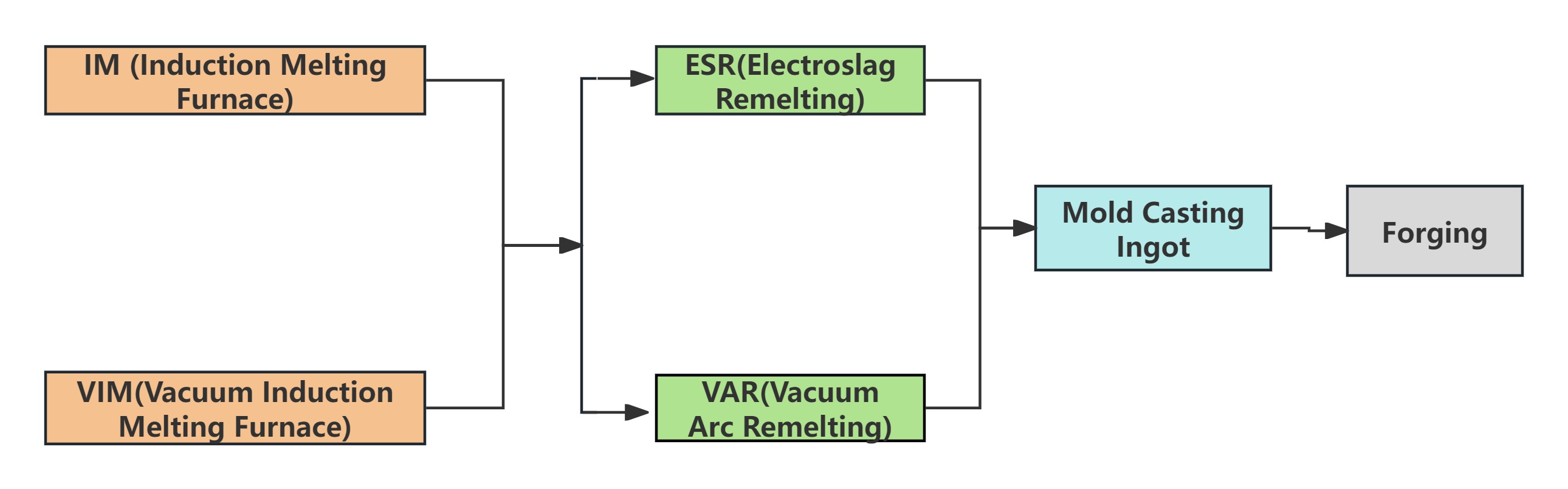

Production Procedure

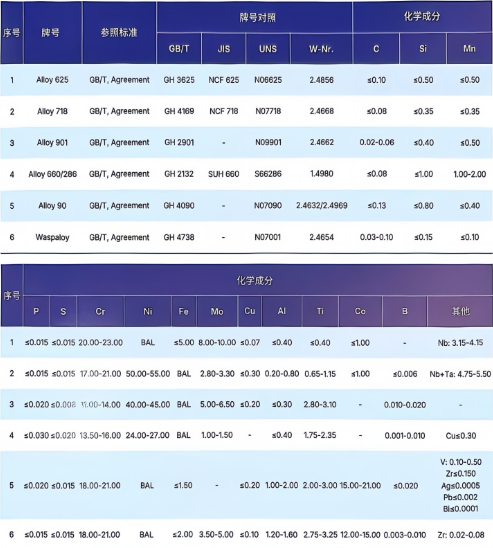

Steel Grade and Chemical Composition

Product Description

1. Size: OD120*L4500, etc

2. Material: Alloy 625/718/901,etc.

3. Heat treatment: Annealing,/Solution/Aging

4. Surface treatment: Polish/Black Surface

5.Shape:Round Bar

6. Transport packaging: Wooden case

7. Service: Customization

8. Warranty period: One year

Application

High temperature alloy core is applied in scenarios that require resistance to high temperatures above 600 ℃, corrosion, or complex stresses, with aerospace, energy and power fields as the core, covering multiple industrial and high-end civilian scenarios.

Aerospace field: the most critical application scenario. Core components such as turbine blades, turbine disks, combustion chambers, and guide vanes used in the manufacturing of aviation engines, as well as high-temperature and pressure bearing components such as rocket engine thrust chambers and nozzles, can withstand temperatures above 1000 ℃ and complex stresses.

Energy and power sector: covering sub scenarios such as gas turbines, nuclear power, and thermal power. The turbine blades, combustion chambers, and other components of gas turbines rely on their high temperature resistance characteristics; The fuel cladding and internal components used in nuclear reactors in the field of nuclear power must withstand both high temperatures and radiation corrosion; In the thermal power industry, it is used for boiler superheaters, reheater pipelines, etc. in ultra supercritical units.

Petrochemical industry: suitable for high temperature, high pressure, and highly corrosive environments. For example, equipment such as ethylene cracking furnace tubes, hydrogenation reactors, and reforming reactors can resist medium corrosion and stress damage at high temperatures.

In the field of shipbuilding and ocean engineering, it is used as the core component of ship gas turbines, as well as high-temperature heat exchange equipment and oil and gas transmission pipelines for offshore platforms, which can withstand high temperatures, high humidity, and corrosion in marine environments.

Other important applications

Automotive industry: mainly used for turbochargers and exhaust system components in high-performance racing cars or high-end models, to enhance the engine's high-temperature resistance and power performance.

In the medical field, cobalt based high-temperature alloys are mainly used to manufacture artificial joints, dental implants, etc., with biocompatibility, wear resistance, and high temperature resistance (sterilization process) characteristics.

In the field of metallurgy and machinery, high-temperature furnace components, heat treatment fixtures, and wear-resistant and corrosion-resistant parts that need to work in high-temperature environments for a long time in mechanical manufacturing are used in the metallurgical industry.

Feature

The core characteristics of high-temperature alloys are high temperature resistance, strong stability, corrosion resistance, and the ability to work reliably for a long time under high temperatures above 600 ℃ and complex stresses.

1.Excellent high-temperature strength: above 600 ℃, it still maintains high tensile strength, creep resistance, and fatigue resistance, and will not undergo significant deformation or fracture due to high temperature.

Strong antioxidant and anti-corrosion ability: A dense oxide film forms on the surface under high temperature environment, which can resist oxidation, gas corrosion, acid and alkali medium corrosion, etc., extending the service life.

2.High organizational stability: It is mostly a single-phase austenitic structure. When used at high temperatures for a long time, the organizational structure is not easily changed and the performance deteriorates slowly.

3.Comprehensive mechanical performance balance: It has certain plasticity, toughness, and wear resistance, can adapt to stress changes under complex working conditions, and has high reliability after processing and forming.

4.Suitable for extreme environments: It can withstand multiple harsh conditions such as high temperature, high pressure, radiation, and vibration, and is the core material under extreme working conditions.

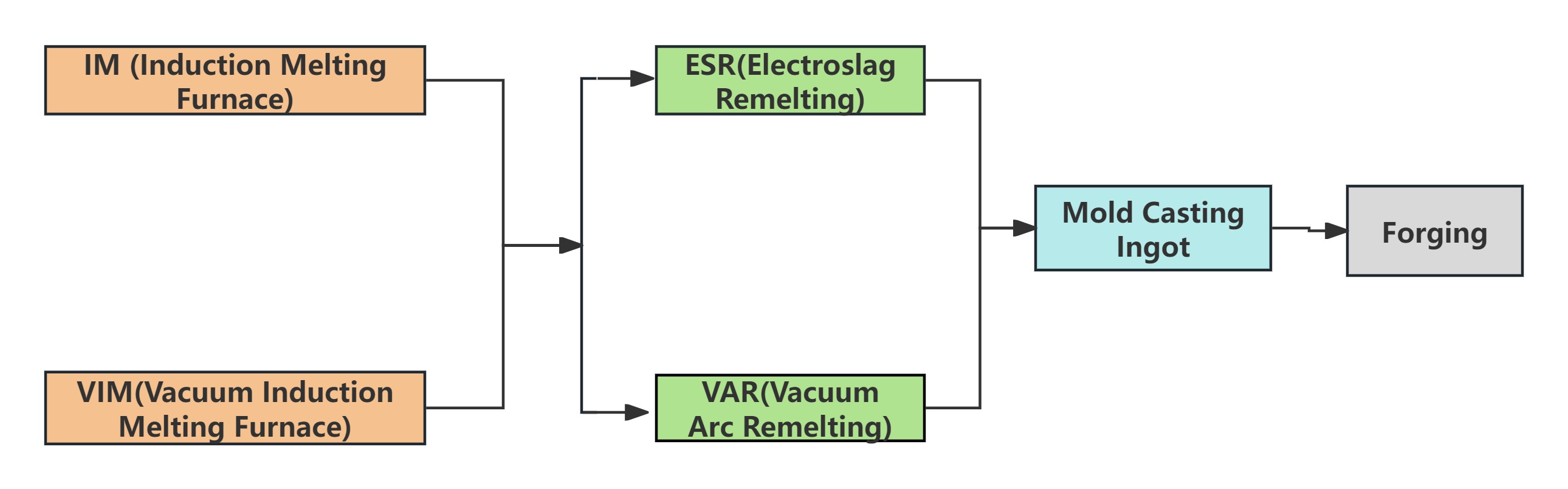

Production Procedure

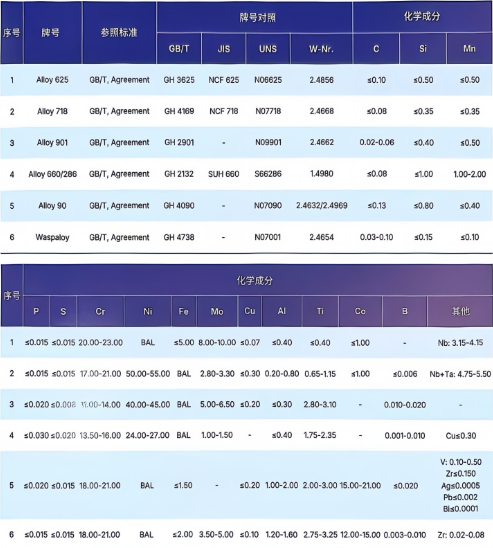

Steel Grade and Chemical Composition

content is empty!