| Availability: | |

|---|---|

| Quantity: | |

FORGE - R-OD260*L2690

ETERNAL

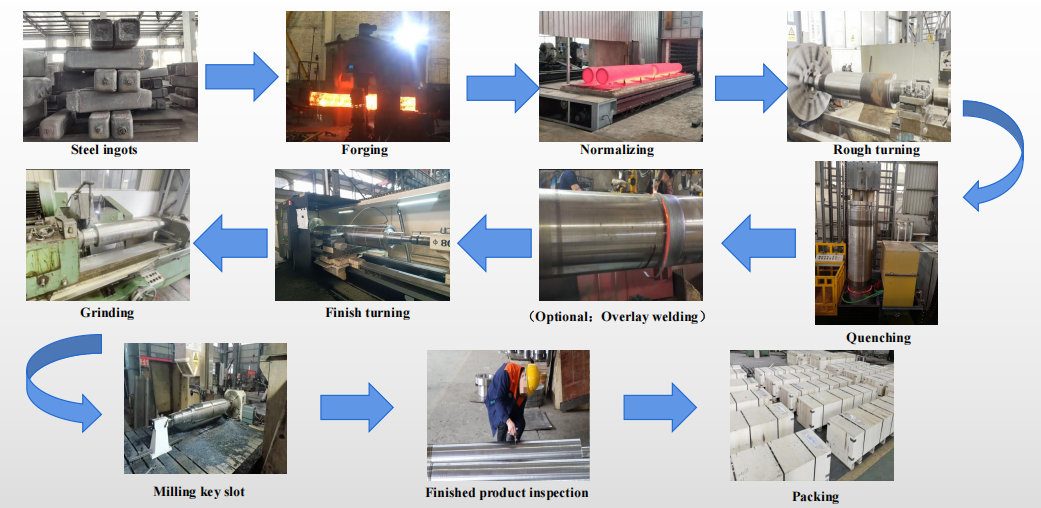

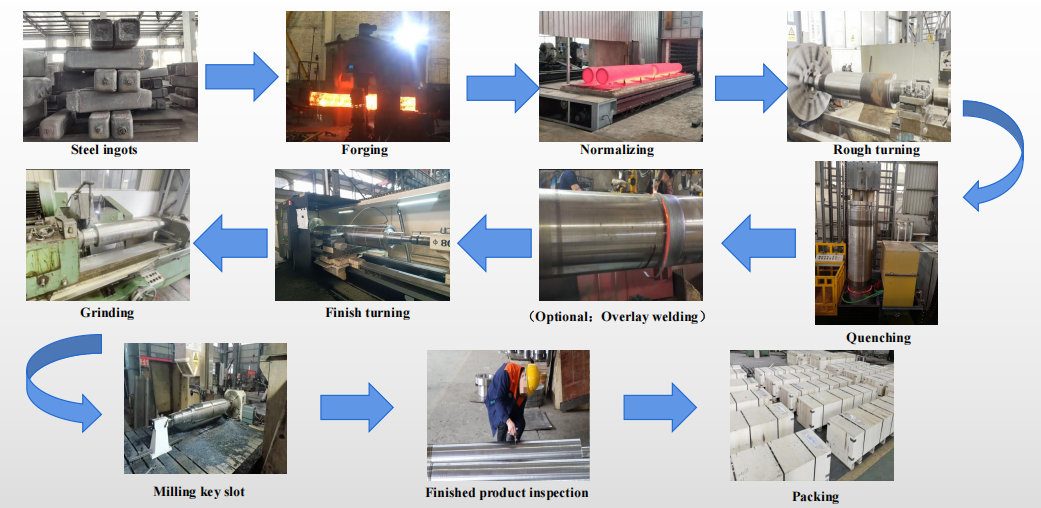

Production Procedure

Application:

Conveyor rollers are widely used in steel plate continuous casting and rolling production lines, playing a crucial role in the heating and conveying of steel billets.

Feature:

High temperature resistance: The conveyor roller at the bottom of the furnace can operate stably for a long time in a high temperature environment, ensuring that it remains undeformed and undamaged.

Good wear resistance: During operation, the furnace bottom conveyor roller is in long-term contact and friction with high-temperature steel billets, requiring good wear resistance to ensure a long service life and avoid frequent replacement due to excessive wear, which would affect production efficiency.

High load-bearing capacity: The furnace bottom conveyor rollers are required to bear the weight of steel billets inside the heating furnace, and ensure stable support and uniform transportation of the billets during the rolling process. Therefore, they must possess a high load-bearing capacity to prevent deformation or damage under heavy loads.

High requirements for surface quality: To avoid affecting the surface quality of steel plates, the surface of the furnace bottom conveyor rollers usually requires special treatment, such as spraying ceramic coatings, to prevent issues such as buildup and scratching of steel billets.

Production Procedure

Application:

Conveyor rollers are widely used in steel plate continuous casting and rolling production lines, playing a crucial role in the heating and conveying of steel billets.

Feature:

High temperature resistance: The conveyor roller at the bottom of the furnace can operate stably for a long time in a high temperature environment, ensuring that it remains undeformed and undamaged.

Good wear resistance: During operation, the furnace bottom conveyor roller is in long-term contact and friction with high-temperature steel billets, requiring good wear resistance to ensure a long service life and avoid frequent replacement due to excessive wear, which would affect production efficiency.

High load-bearing capacity: The furnace bottom conveyor rollers are required to bear the weight of steel billets inside the heating furnace, and ensure stable support and uniform transportation of the billets during the rolling process. Therefore, they must possess a high load-bearing capacity to prevent deformation or damage under heavy loads.

High requirements for surface quality: To avoid affecting the surface quality of steel plates, the surface of the furnace bottom conveyor rollers usually requires special treatment, such as spraying ceramic coatings, to prevent issues such as buildup and scratching of steel billets.

content is empty!